BOSCH REXROTH

R901350272

$698.77 USD

- BOSCH REXROTH

- Material:R901350272

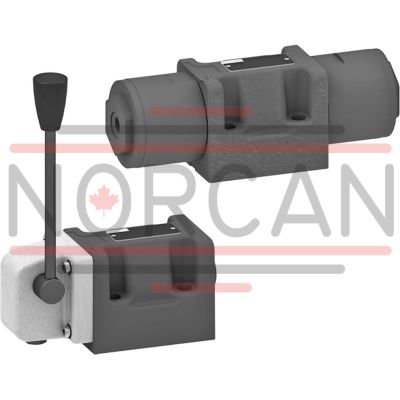

- Model:4WMM 10 D5X/F/M GO2

Quantity in stock: 0

The Bosch Rexroth 4WMM10D5X/F/M (R901350272) is a high-performance industrial hydraulic valve designed for manual operation. This spool valve is direct-actuated with a hand lever and features detent locking, ensuring reliable control over the start, stop, and direction of oil flow according to its hydraulic symbol D. It is suitable for subplate mounting with a CETOP size D connection diagram that conforms to ISO standards. The 4WMM10D5X/F/M valve has multiple ports and offers a maximum operating pressure of up to 350 bar, catering to demanding hydraulic applications. With its robust construction, this valve can handle maximum flow rates efficiently while maintaining precise control over the hydraulic system. The NBR seals within the valve make it compatible with a variety of hydraulic fluids including HL, HLP, HLPD, HVLP, HVLPD, and HFC. Additionally, the valve's design comprises a housing unit, control spool, hand lever actuation type, and one or two return springs which secure the spool in its central or initial position when de-energized. Users can shift the spool to desired positions using the hand lever actuation method. For instances where operational conditions cause flows that exceed the valve's performance limit during switching processes, the use of a throttle insert may be necessary. With its versatile application capabilities and robust design features such as multiple switching positions and an optional throttle insert for flow regulation during peak operations, the Bosch Rexroth 4WMM10D5X/F/M is an essential component in manual directional control applications within various hydraulic systems.

Size 10, symbol D, manually operated

Industrial hydraulic valve in a high performance range. Reliable switch-over of the oil flow direction according to hydraulic symbol.

Unpacked Weight: 3.600 kg

Valves of type WMM are manually actuated directional spool valves.

They control the start, stop and direction of a flow.

The directional valves basically consist of housing (1), one type of actuation (2.1) (hand lever), control spool (3) and one or two return springs (4).

When de-energized, the control spool (3) is held in the central position or in the initial position by the return springs (4) (except for version "O").

The control spool (3) is moved to the desired spool position by means of the types of actuation.

Type 4WMM 10 D5X/F/... (with detent)

Type 4WMM 10 E5X/...

Throttle insert

The use of a throttle insert is required when, due to prevailing operating conditions, flows occur during the switching processes which exceed the performance limit of the valve.

| Spool valve |

| Direct actuated |

| With detent locking |

| Maximum flow 160 l/min |

| Component series 5X |

| Size 10 |

| Maximum operating pressure 350 bar |

| Data Sheet | Download Data Sheet |

| 3D CAD | Download 3D CAD |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Spool symbol | Symbol D |

| Max. pressure | 350 |

| Productgroup ID | 9,10,11,12,13,14 |

| Number of ports | 4 |

| Type of actuation | with manual actuation |

| Size | 10 |

| Max. flow | 160 |

| Type of connection | Subplate mounting |

| Size_CETOP | D05 |

| Connection diagram | ISO 4401-05-04-0-05 |

| Number of switching positions | 2 |

| Weight | 3.600 |

| Seals | NBR |

| Hydraulic fluid | HL,HLP,HLPD,HVLP,HVLPD,HFC |

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

||

|

WMM |

10 |

5X |

/ |

/ |

– |

* |

|

01 |

3 main ports |

3 |

||

|

4 main ports |

4 |

|||

|

Types of actuation |

||||

|

02 |

Manually: hand lever |

WMM |

||

|

03 |

Size 10 |

10 |

||

|

04 |

Symbols e. g. C, E, EA, EB, etc.; for the possible version, see Symbols and Types of actuation |

|||

|

05 |

Component series 50 … 59 (50 … 59: unchanged installation and connection dimensions) |

5X |

||

|

06 |

With spring return |

no code |

||

|

With detent |

F |

|||

|

Corrosion protection |

||||

|

07 |

Standard corrosion protection |

no code |

||

|

Improved corrosion protection (720 h salt spray test according to EN ISO 9227) |

J4 |

|||

|

Throttle insert1) |

||||

|

08 |

Without throttle insert |

no code |

||

|

With throttle insert: |

||||

|

Connection |

Throttle Ø in mm |

|||

|

0,8 mm |

1,0 mm |

1,2 mm |

||

|

P |

B08 |

B10 |

B12 |

|

|

A |

H08 |

H10 |

H12 |

|

|

B |

R08 |

R10 |

R12 |

|

|

A and B |

N08 |

N10 |

N12 |

|

|

T 2) |

X08 |

X10 |

X12 |

|

|

Further throttle insert diameters upon request. |

||||

|

Seal material |

||||

|

09 |

NBR seals |

M |

||

|

FKM seals |

V |

|||

|

Seals for HFC hydraulic fluids |

MH |

|||

|

Observe compatibility of seals with hydraulic fluid used. |

||||

|

Pilot oil port |

||||

|

10 |

Whitworth pipe thread G1/4 |

‒ |

||

|

11 |

Further details in the plain text |

* |

||

| 1) When the admissible valve performance limit is exceeded, throttle inserts are to be installed (see Performance limits). | |

| 2) When throttle inserts are used in channel T, the pressure in the working ports and in case of connection to the tank chambers must not exceed 210 bar. |

general

|

Size |

10 | ||

|

Weight |

Valve with one actuation cylinder |

kg |

3.6 |

|

Valve with two actuation cylinders |

kg |

3.6 | |

|

Operating force |

with detent "F" |

N |

30 … 40 |

|

With spring return |

N |

18 … 20 | |

|

Installation position |

any | ||

|

Ambient temperature range |

NBR seals |

°C |

-20 … +70 |

|

FKM seals |

°C |

-15 … +70 | |

|

Storage temperature range |

°C |

-20 … +50 | |

hydraulic

|

Size |

10 | ||

|

Maximum operating pressure |

Port P |

bar |

350 |

|

Port A |

bar |

350 | |

|

Port B |

bar |

350 | |

|

Port T 1) |

bar |

210 | |

|

Maximum flow |

l/min |

160 | |

|

Hydraulic fluid |

see table | ||

|

Hydraulic fluid temperature range 2) |

NBR seals |

°C |

-20 … +80 |

|

FKM seals |

°C |

-15 … +80 | |

|

Viscosity range |

mm²/s |

2.8 … 500 | |

|

Maximum admissible degree of contamination of the hydraulic fluid 3) |

Class 20/18/15 according to ISO 4406 (c) | ||

| 1) | With symbols A or B, port T must be used as leakage oil connection if the operating pressure exceeds the admissible tank pressure. |

| 2) | at the valve working ports of the valve |

| 3) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

|

|

Mineral oils and related hydrocarbons |

HL, HLP, HLPD, HVLP, HVLPD |

NBR, FKM |

DIN 51524 |

|

|

Bio-degradable |

Insoluble in water |

HETG |

NBR, FKM |

VDMA 24568 |

|

HEES |

FKM |

|||

|

Soluble in water |

HEPG |

FKM |

VDMA 24568 |

|

|

Containing water |

Water-free |

HFDU, HFDR |

FKM |

ISO 12922 |

|

Containing water |

HFC (Fuchs Hydrotherm 46M, Petrofer Ultra Safe 620) |

NBR

|

ISO 12922 |

|

|

Important information on hydraulic fluids! For further information and data on the use of other hydraulic fluids, please refer to data sheet 90220 or contact us! There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.)!Flame-resistant – containing water: Maximum pressure differential per control edge 50 bar. Pressure pre-loading at the tank port >20% of the pressure differential; otherwise, increased cavitation Life cycle compared to operation with mineral oil HL, HLP 50 to 100 % |

||||

For applications outside these parameters, please consult us!

(measured with HLP46, ϑOil = 40 ±5 °C)

Δp-qV characteristic curves

|

Symbol |

Direction of flow |

|||

|

P ‒ A |

P ‒ B |

A ‒ T |

B ‒ T |

|

|

A; B |

6 |

6 |

‒ |

‒ |

|

C |

1 |

2 |

5 |

7 |

|

D |

2 |

2 |

5 |

7 |

|

E |

17 |

16 |

19 |

21 |

|

F |

2 |

3 |

22 |

23 |

|

G |

4 |

4 |

24 |

24 |

|

H |

14 |

14 |

20 |

21 |

|

J |

3 |

3 |

9 |

11 |

|

J73 |

22 |

21 |

23 |

24 |

|

L |

3 |

3 |

9 |

9 |

|

M |

14 |

14 |

6 |

8 |

|

P |

17 |

14 |

20 |

23 |

|

Q |

16 |

17 |

4 |

8 |

|

R |

18 |

21 |

18 |

24 |

|

T |

18 |

4 |

10 |

24 |

|

U |

3 |

3 |

6 |

11 |

|

V |

17 |

17 |

18 |

20 |

|

W |

upon request |

|||

|

Central position: |

|||||

|

Symbol |

Direction of flow |

||||

|

P ‒ A |

P ‒ B |

B ‒ T |

A ‒ T |

P ‒ T |

|

|

H |

12 |

12 |

13 |

13 |

15 |

Notice!

The specified performance limits are valid for use with two directions of flow (e. g. from P to A and simultaneous return flow from B to T).

Due to the flow forces acting within the valves, the admissible performance limit may be considerably lower with only one direction of flow (e. g. from P to A while port B is blocked)!

In such use cases, please consult us!

Performance limits (measured with HLP46, ϑOil = 40 ±5 °C)

|

With spring return “–” |

|

|

Characteristic curve |

Symbol |

|

1 |

C, D, E, J, J73, L, M, Q, U, V, W |

|

2 |

H |

|

3 |

T, G |

|

With detent "F" |

|

|

Characteristic curve |

Symbol |

|

4 |

C, D, E, J, J73, L, M, Q, U |

|

5 |

T, G, H |

| 1) | Example:Symbol E with spool position “a” → ordering code ..EA..Symbol E with spool position “b" → ordering code ..EB.. |

Size 16

Dimensions in mm

Dimensions in mm

|

1 |

Valves with 2 spool positions, symbol B and .B |

|

2 |

Valves with 2 switching positions, symbol A, C, D .A |

|

3 |

Valves with 3 switching positions |

|

4 |

Cover and hand lever |

|

5 |

Name plate |

|

6 |

Identical seal rings for port A, B, P, TA, TB |

|

7 |

Additional port TB can optionally be used |

|

8 |

Porting pattern according to ISO 4401-05-04-0-05 |

Notices!

Deviating from ISO 4401, port T is called TA and port T1 is called TB in this data sheet. For valves with 2 switching positions and symbols B and .B, the hand lever is installed on valve side B. The dimensions are nominal dimensions which are subject to tolerances.