BOSCH REXROTH

R901443821

$2,744.73 USD

- BOSCH REXROTH

- Material:R901443821

- Model:DBET-6X/350YG24-8K4V

Quantity in stock: 0

The Bosch Rexroth DBET-6X/350YG24-8K4V (R901443821) is a direct-operated proportional pressure relief valve designed with seat architecture for effective system pressure limitation. The valve is engineered to deliver precise control by converting electrical signals into mechanical force, which regulates the hydraulic flow and system pressure. It features a proportional solenoid with central thread and a detachable coil, ensuring reliable performance and ease of maintenance. This high-performance industrial hydraulic valve supports subplate mounting and conforms to ISO connection diagram standards, including NFPA T3.5.1 R2 D03 SizeCETOP 3. With its robust construction, the DBET-6X/350YG24-8K4V can handle a maximum operating pressure of up to 350 bar and is capable of accommodating a maximum flow rate as specified in its technical documentation. The valve's electrical actuation requires an external amplifier and operates on a supply voltage of 24 VDC, connecting via an electrical connector with Connector pole + PE according to EN 175301-803 standards. The type of actuation is electrical with external electronics, which allows for fine-tuning of command value pressure characteristic curves through adjustable ramps. Suitable for various hydraulic fluids such as HL, HLP, HLPD, HVLP, HVLPD, HETG, HEES, HEPG, HFDU, and HFDR, the DBET-6X/350YG24-8K4V ensures compatibility across a wide range of applications while offering reliable performance thanks to its FKM seals. With its number of ports and switching positions detailed in the specifications, this Bosch Rexroth valve stands out for its precision in controlling system pressures within demanding industrial environments.

Size 6, P → T, P → Y, electrical with external amplifier, 24 V DC

Industrial hydraulic valve in a high performance range. Reliable limitation of the pressure to the command value signal.

Unpacked Weight: 1.4 kg

General information

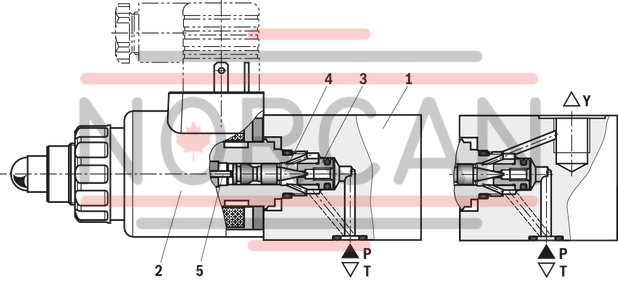

Proportional pressure relief valves of type DBET are remote control valves with seat design and are used for system pressure limitation. Operation by means of a proportional solenoid with central thread and detachable coil. The interior of the solenoid is connected to port T or Y and is filled with the hydraulic fluid. Dependent on the electric command value, these valves can be used to steplessly set the system pressure to be limited. The valves mainly consist of the housing (1), a proportional solenoid (2), the valve seat (3) and the valve poppet (4).

Basic principle

For the setting of the system pressure, a command value is specified at the control electronics. Dependent on the command value, the electronics actuate the solenoid coil with electric current. The proportional solenoid converts the electric current into mechanical force that acts on the valve poppet (4) via the armature plunger (5). The valve poppet (4) pushes onto the valve seat (3) and blocks the connection between port P and T or Y. If the hydraulic force on the valve poppet (4) equals the solenoid force, the valve controls the set pressure by lifting the valve poppet (4) off the valve seat (3) and thus enabling hydraulic fluid to flow from port P to T or Y. If the command value is zero, the control electronics only apply the minimum control current to the proportional solenoid (2) and the minimum set pressure is set.

Type DBET

| Pressure rating 350 bar |

| Direct actuated |

| Proportional pressure valve in poppet seat design |

| Component series 6X |

| Size 6 |

| Maximum flow 2 l/min |

| Maximum operating pressure 420 bar |

| Data Sheet | Download Data Sheet |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Spool symbol | P → T, P → Y |

| Max. pressure | 420 |

| Electrical connection description | Connector 3-pole (2 + PE) according to EN 175301-803 |

| Productgroup ID | 9,10,11,12,13,14 |

| Number of ports | 3 |

| Type of actuation | Electrical with external electronics |

| Size | 6 |

| Electrical connector | Connector 3-pole (2 + PE) |

| Max. flow | 2 |

| Type of connection | Subplate mounting |

| Connection diagram NFPA | NFPA T3.5.1 R2-2002 D03 |

| Size_CETOP | D03 |

| Connection diagram | ISO 4401-03-02-0-05 |

| Supply voltage | 24 VDC |

| Number of switching positions | 2 |

| Weight | 1.4 |

| Seals | FKM |

| Hydraulic fluid | HL,HLP,HLPD,HVLP,HVLPD,HETG,HEES,HEPG,HFDU,HFDR |

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

||

|

DBET |

‒ |

6X |

/ |

G24 |

K4 |

* |

|

01 |

Proportional pressure relief valve for external control electronics |

DBET |

|

02 |

Component series 60 … 69 (60 … 69: unchanged installation and connection dimensions) |

6X |

|

Maximum pressure rating |

||

|

03 |

Up to 50 bar |

50 |

|

Up to 100 bar |

100 |

|

|

Up to 200 bar |

200 |

|

|

Up to 315 bar |

315 |

|

|

Up to 350 bar |

350 |

|

|

Up to 420 bar |

420 |

|

|

04 |

Pilot oil return, internal |

no code |

|

Pilot oil return, external |

Y |

|

|

05 |

Direct voltage 24 V |

G24 |

|

06 |

1600 mA coil |

no code |

|

800 mA coil (only possible for DBET-6X (external control electronics) |

-8 1) |

|

|

Electrical connection |

||

|

07 |

Without mating connector; connector DIN EN 175301-803 |

K4 |

|

Seal material |

||

|

08 |

NBR seals |

M |

|

FKM seals |

V |

|

|

Observe compatibility of seals with hydraulic fluid used. (Other seals upon request) |

||

|

09 |

Further details in the plain text |

* |

|

1) |

Replacement for series 5X. (Attention! External amplifiers only suitable for G24 = 1.6 A solenoid), |

|

For applications outside these parameters, please consult us!

general

|

Type |

DBET | |

|

Size |

6 | |

|

Component series |

6X | |

|

Weight |

kg |

2 |

|

Installation position |

Any | |

|

Ambient temperature range |

°C |

-20 … +70 |

hydraulic

|

Type |

DBET | |||

|

Maximum operating pressure |

Port P |

bar |

420 | |

|

Return flow pressure |

Port T (Y) |

separate and depressurized to the tank | ||

|

Maximum set pressure |

Pressure rating 50 bar |

bar |

50 | |

|

Pressure rating 100 bar |

bar |

100 | ||

|

Pressure rating 200 bar |

bar |

200 | ||

|

Pressure rating 315 bar |

bar |

315 | ||

|

Pressure rating 350 bar |

bar |

350 | ||

|

Pressure rating 420 bar |

bar |

420 | ||

|

Minimum set pressure 1) |

at a command value of 0 |

See characteristic curves | ||

|

Maximum flow 2) |

l/min |

2 | ||

|

Hydraulic fluid |

see table | |||

|

Hydraulic fluid temperature range |

°C |

-20 … +80 | ||

|

Viscosity range |

mm²/s |

20 … 380 | ||

|

preferably |

mm²/s |

30 … 46 | ||

|

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 3) |

Class 20/18/15 according to ISO 4406 (c) | |||

|

Hysteresis 4) |

% |

< 4 | ||

|

Range of inversion 4) |

% |

< 0.5 | ||

|

Response sensitivity 4) |

% |

< 0.5 | ||

|

Linearity 4) |

% |

± 3 | ||

|

Manufacturing tolerance of the command value pressure characteristic curve, related to 0.8 l/min; pressure increasing |

at command value 20 % 5) |

% |

< ± 1.5 | |

|

at command value 100 % 6) |

% |

< ± 5 | ||

|

Step response |

0% → 100% 7) |

ms |

80 | |

|

100% → 0% 7) |

ms |

80 | ||

| 1) | at command value 0 V or 4 mA |

| 2) | Observe flow limitation for pressure ratings 315, 350 and 420 bar. |

| 3) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

| 4) | Of the maximum set pressure |

| 5) | Of the maximum set pressure, zero point calibration at the factory |

| 6) | of the maximum set pressure, comparison possible at the external control electronics |

| 7) | Line volume < 20 cm3; qV = 0.8 l/min; depending on the system |

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

|

Mineral oils and related hydrocarbons |

HL, HLP |

NBR / FKM |

DIN 51524 |

|

Bio-degradable - insoluble in water |

HEES |

FKM |

VDMA 24568 |

|

Flame-resistant - water-free |

HFDU |

FKM |

ISO 12922 |

|

Flame-resistant - containing water |

HFC (Fuchs HYDROTHERM 46M, Petrofer Ultra Safe 620) |

NBR |

ISO 12922 |

|

Important information on hydraulic fluids: For more information and data on the use of other hydraulic fluids please contact us. There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.). The flash point of the process and operating medium used must be 40 K over the maximum solenoid surface temperature.

Flame-resistant - containing water: Bio-degradable: When using hydraulic fluids that are simultaneously zinc-solving, zinc may accumulate (700 mg zinc per pole tube). |

|||

electrical

|

Type |

DBET | |||

|

Minimum solenoid current |

with 1600 mA - coil |

mA |

≤ 100 | |

|

with 800 mA - coil |

mA |

≤ 100 | ||

|

Maximum solenoid current |

with 1600 mA - coil |

mA |

1760 | |

|

with 800 mA - coil |

mA |

840 | ||

|

Solenoid coil resistance |

Cold value at 20 °C |

with 1600 mA - coil |

Ω |

5.5 |

|

with 800 mA - coil |

Ω |

20.6 | ||

|

Maximum hot value |

with 1600 mA - coil |

Ω |

8.05 | |

|

with 800 mA - coil |

Ω |

33 | ||

|

Duty cycle |

% |

100 | ||

|

Power supply |

V DC |

24 | ||

|

Supply voltage range |

V DC |

21 … 35 | ||

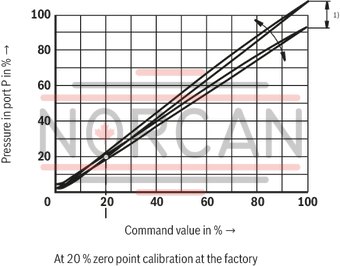

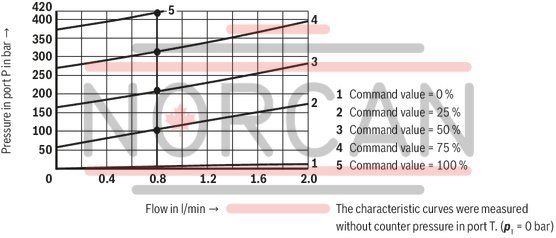

(measured with HLP46, ϑOil = 40 ±5 °C)

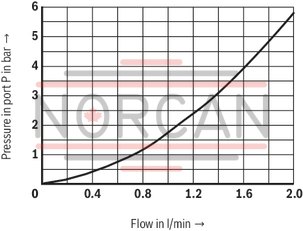

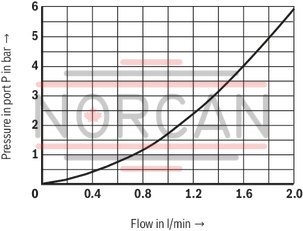

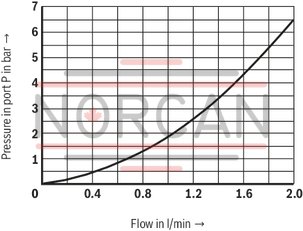

Pressure in port P dependent on the command value (flow = 0.8 l/min)

| 1) | 1) With valve type DBET, the manufacturing tolerance at the external amplifier can be changed using the command value attenuator potentiometer "Gw". The digital amplifier is set using the "Limit” parameter. Here, the control current according to the technical data must not be exceeded. In order to be able to adjust several valves to the same characteristic curve, do not set the pressure higher than the maximum set pressure of the pressure rating with command value 100%. |

Pressure in port P dependent on command value /Comparison DBET series 5X-6X / Pressure rating 200 bar (with amplifier VT-VSPA-1-1X with 800 mA coil)

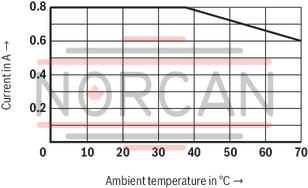

Current drop with increasing ambient temperature, 24 V and 100% duty cycle

| 1) |

Notice: With increased temperature, the solenoid current will drop. Thus, the set pressure differs accordingly. |

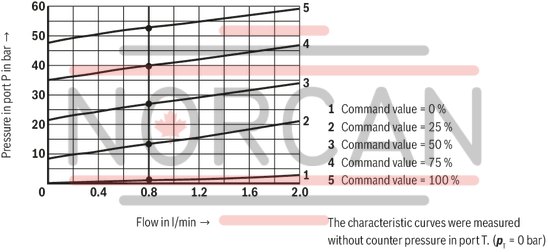

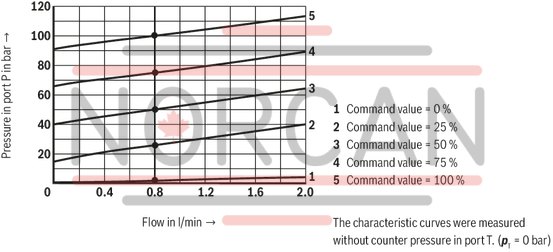

Pressure rating 50 bar

Pressure rating 100 bar

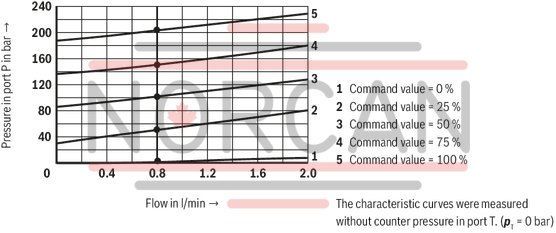

Pressure rating 200 bar

Pressure rating 315 bar

| 1) | In case of characteristic curve 5, the command value may not exceed the maximum flow of 1.4 l/min |

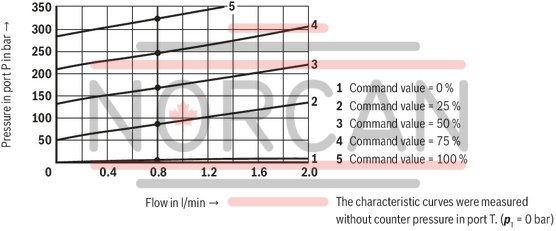

Pressure rating 350 bar

| 1) | In case of characteristic curve 5, the command value may not exceed the maximum flow of 0.8 l/min |

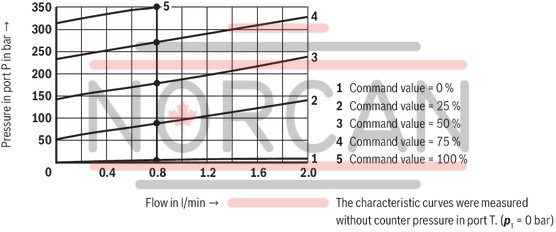

Pressure rating 420 bar

| 1) | In case of characteristic curve 5, the command value may not exceed the maximum flow of 0.8 l/min |

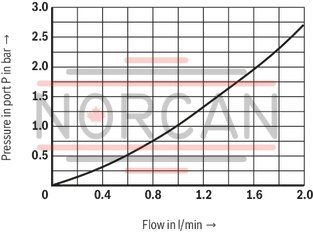

Pressure rating 50 bar

Pressure rating 100 bar

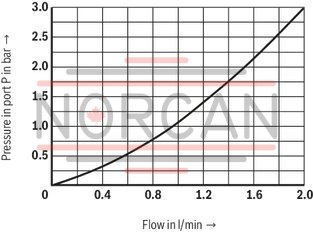

Pressure rating 200 bar

Pressure rating 315 bar

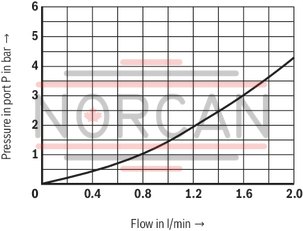

Pressure rating 350 bar

Pressure rating 420 bar

Notice:

The characteristic curves were measured without counter pressure in port T. (Pt = 0 bar)

Minimum control current ≤ 100 mA

(This current is reached with a command value of 0 V and/or 4 mA.)

Pilot oil return, internal

Pilot oil return, external

Connection at mating connector

Connection at the connector

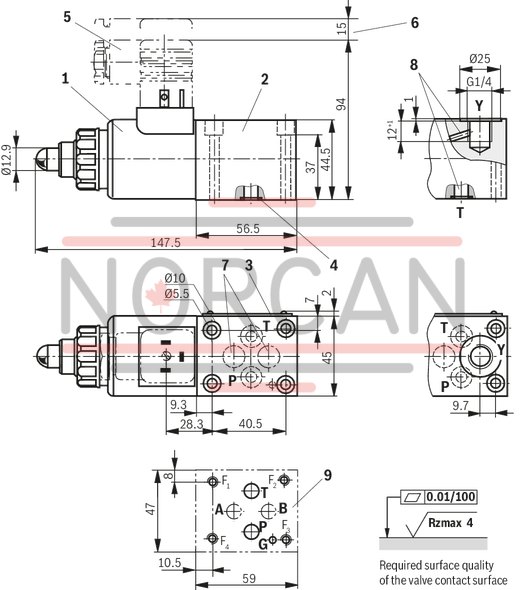

Dimensions in mm

|

1 |

Proportional solenoid |

|

2 |

Valve housing |

|

3 |

Name plate |

|

4 |

Identical seal rings for ports A, B, P, and T |

|

5 |

mating connector according to DIN EN 175301-803 |

|

6 |

Space required to remove the mating connector |

|

7 |

Blind counterbores A and B |

|

8 |

With version ..Y.. (external pilot oil return) port Y is internally connected to port T. Port T is not plugged. |

|

9 |

Machined valve contact surface; porting pattern according to ISO 4401-03-02-0-05 |

Recommended valve mounting screws (separate order):

4 hexagon socket head cap screws ISO 4762 - M5 x 45 - 10.9-flZn-240h-L

Tightening torque MA = 7 Nm ± 10%; material no. R913000140

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z4

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z4

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair