BOSCH REXROTH

R901454049

$89.02 USD

- BOSCH REXROTH

- Material:R901454049

- Model:S6A50-1X/450J3

Quantity in stock: 0

The Bosch Rexroth S6A50-1X/450J3 (R901454049) is a high-performance, hydraulically actuated industrial hydraulic valve designed for reliable blocking of oil flow at selected ports. This direct-actuated seat valve is part of component series X and features a spool symbol A B, ensuring precise control in hydraulic systems. It is capable of handling a maximum pressure with an electrical connection that simplifies integration into various circuits. With its threaded connection type, the S6A50-1X/450J3 valve offers a secure and easy installation process. The number of ports and switching positions, along with the max flow rate, are engineered to meet the demanding requirements of complex hydraulic tasks. The valve's size and weight are optimized for its function while maintaining robustness and durability. Compatible with a wide range of hydraulic fluids, including HL, HLP, HLPD, HVLP, HVLPD, HETG, HEES, HEPG, HFDU, HFDR, and HFC types, this Bosch Rexroth valve ensures versatility across different systems. Additionally, it features leakage-free blocking in one direction and offers various optional cracking pressures to cater to specific application needs. With its maximum operating pressure (bar) and maximum flow (l/min) ratings specified in the product details, the S6A50-1X/450J3 valve stands out as an efficient solution for controlling fluid dynamics in industrial environments. Whether used in manufacturing equipment or other heavy-duty applications requiring precise hydraulic control, this Bosch Rexroth valve delivers performance that industry professionals rely on.

Size 6, A → B, hydraulically actuated

Industrial hydraulic valve in a high performance range. Reliable blocking of the oil flow at selected ports.

Unpacked Weight: 0.127 kg

| Seat valve |

| Direct actuated |

| Size 6 … 30 |

| Maximum operating pressure 450 bar |

| Component series 1X |

| Maximum flow 450 l/min |

| Data Sheet | Download Data Sheet |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Spool symbol | A → B |

| Max. pressure | 450 |

| Electrical connection description | 0 |

| Productgroup ID | 9,10,11,12,13,14 |

| Number of ports | 2 |

| Size | 6 |

| Max. flow | 18 |

| Type of connection | Threaded connection |

| Connection diagram | Pipe thread G1/4 ISO 228-1 |

| Number of switching positions | 2 |

| Weight | 0.127 |

| Hydraulic fluid | HL,HLP,HLPD,HVLP,HVLPD,HETG,HEES,HEPG,HFDU,HFDR,HFC |

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

||

|

S |

A |

- |

1X |

/ |

|

Type |

||

|

01 |

Isolator valve |

S |

|

Size |

||

|

02 |

Size 6 |

6 |

|

Size 8 |

8 |

|

|

Size 10 |

10 |

|

|

Size 15 |

15 |

|

|

Size 20 |

20 |

|

|

Size 25 |

25 |

|

|

Size 30 |

30 |

|

|

Connection |

||

|

03 |

Threaded connection |

A |

|

Cracking pressure (see characteristic curves) |

||

|

04 |

0 bar (without spring) |

00 |

|

0,2 bar |

02 |

|

|

0.5 bar (standard) |

05 |

|

|

1,5 bar |

15 |

|

|

3,0 bar |

30 |

|

|

5 bar |

50 |

|

|

8 bar (only NG25 and 30) |

80 |

|

|

Component series |

||

|

05 |

Component series 10 ... 19 (10 ... 19: unchanged installation and connection dimensions) |

1X |

|

Maximum operating pressure |

||

|

06 |

Maximum operating pressure 420 bar (Nominal size 25 and 30) |

420 |

|

Maximum operating pressure 450 bar (Nominal size 6 ... 20) |

450 |

|

|

Corrosion resistance |

||

|

07 |

Improved corrosion protection (240 h salt spray test according to EN ISO 9227) |

J3 |

|

High corrosion protection (720 h salt spray test according to EN ISO 9227) |

J5 |

|

|

Piston bore (orifice in channel B) |

||

|

08 |

Without piston bore |

no code |

|

Thread M4; not fitted |

B00 |

|

|

Orifice Ø1.0 mm |

B10 |

|

|

Orifice Ø1.2 mm |

B12 |

|

|

Orifice Ø1.5 mm |

B15 |

|

|

Connection thread 1) |

||

|

09 |

Pipe thread "G" according to ISO 228-1 |

no code |

|

Pipe thread "M" according to ISO 261 |

/2 |

|

|

Pipe thread “UNF/UN” according to ANSI/ASME B 1.1 |

/12 |

|

| 1) | Other versions available on request |

general

|

Size |

6 | 8 | 10 | 15 | 20 | 25 | 30 | |

|

Weight |

kg |

0.1 | 0.2 | 0.3 | 0.5 | 1 | 2 | 2.5 |

|

MTTFD values according to EN ISO 13849 |

Years |

150 1) | ||||||

| 1) | Not for version "00"; Certificate "Assumed exclusion of faults according to EN ISO 13849-2:2012-10 tab. C4" available upon request. For further details, see data sheet 08012 |

hydraulic

|

Size |

6 | 8 | 10 | 15 | 20 | 25 | 30 | |

|

Maximum operating pressure 1) |

bar |

450 | 420 | |||||

|

Cracking pressure |

See characteristic curves | |||||||

|

Maximum flow |

See characteristic curves | |||||||

|

Hydraulic fluid |

see table | |||||||

|

Hydraulic fluid temperature range |

°C |

-30 … +80 | ||||||

|

Viscosity range |

mm²/s |

2.8 … 500 | ||||||

|

Maximum admissible degree of contamination of the hydraulic fluid 2) |

Class 20/18/15 according to ISO 4406 (c) | |||||||

| 1) | Maximum operating pressures up to 1000 bar upon request. |

| 2) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

|

Hydraulic fluid |

Classification |

Standards |

Data sheet |

|

|

Mineral oils |

HL,HLP, HLPD, HVLP, HVLPD |

DIN 51524 |

90220 |

|

|

Bio-degradable 1) |

Insoluble in water |

HETG |

ISO 15380 |

90221 |

|

HEES |

||||

|

Soluble in water |

HEPG |

ISO 15380 |

||

|

Flame-resistant |

Water-free |

HFDU (glycol base) |

||

|

HFDU (ester base) 1) |

ISO 12922 |

90222 |

||

|

Containing water 1) |

HFC (Fuchs Hydrotherm 46M, Petrofer Ultra Safe 620) |

ISO 12922 |

90223 |

|

|

Important information on hydraulic fluids: For further information and data on the use of other hydraulic fluids, please refer to the data sheets above or contact us. There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.). The ignition temperature of the hydraulic fluid used must be 50 K higher than the maximum surface temperature. Flame-resistant – containing water: Life cycle as compared to operation with mineral oil HL, HLP 30 … 100% Maximum hydraulic fluid temperature 60 °C |

||||

| 1) | Small amounts of dissolved zinc may get into the hydraulic system during use. |

For applications outside these parameters, please consult us!

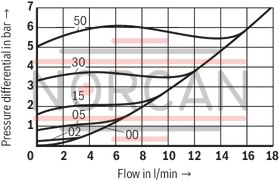

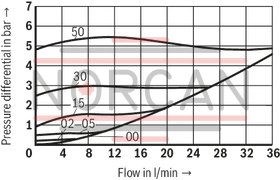

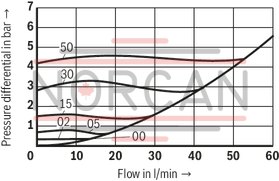

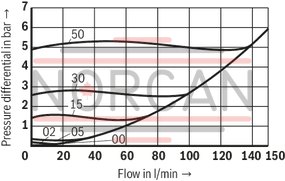

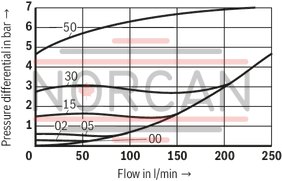

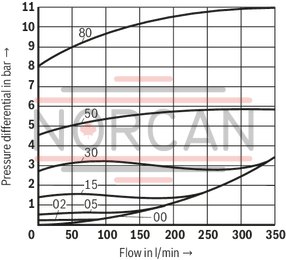

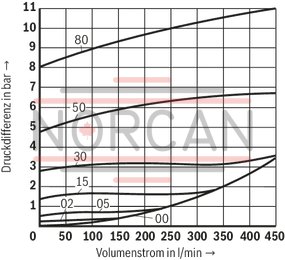

(measured with HLP46, ϑOil = 40 ±5 °C)

∆p-qV characteristic curves with cracking pressure

Size 6

Size 8

Size 10

Size 15

Size 20

Size 25

Size 30

Without spring

With spring

With piston bore/orifice

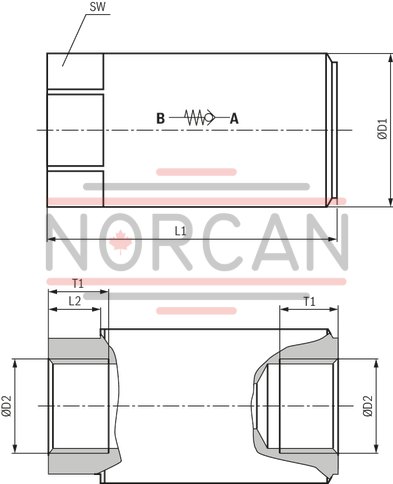

Dimensions in mm

|

NG |

6 | 8 | 10 | 15 | 20 | 25 | 30 | |||

|

ØD1 |

mm |

22.5 | 28 | 34 | 34 | 42 | 52 | 68 | 74.5 | |

|

D2 |

G |

G1/4 | G3/8 | - | G1/2 | G3/4 | G1 | G1 1/4 | G1 1/2 | |

|

M |

M14 x 1,5 | M18 x 1,5 | - | M22 x 1.5 | M27 x 2 | M33 x 2 | M42 x 2 | M48 x 2 | ||

|

UNF/UN |

- | - | 3/4-16 UNF | 3/4-16 UNF | 1 1/6-12 UN | 1 5/16-12 UN | 1 5/8-12 UN | 1 7/8-12 UN | ||

|

L1 |

G |

mm |

58 | 58 | - | 72 | 88 | 98 | 120 | 132 |

|

M |

mm |

58 | 58 | - | 72 | 88 | 98 | 120 | 132 | |

|

UNF/UN |

mm |

- | - | 66 | 72 | 92 | 105 | 120 | 132 | |

|

L1 |

mm |

- | 160 1) | 168 1) | ||||||

|

L2 |

mm |

10.5 | 11.5 | 13 | 13 | 15.5 | 19 | 25 | 28 | |

|

T1 |

G |

mm |

13 | 13 | - | 15 | 18 | 19 | 22 | 22.5 |

|

M |

mm |

12 | 12 | - | 14 | 16 | 18 | 20 | 22 | |

|

UNF/UN |

mm |

- | - | 15 | 15 | 20 | 20 | 20 | 20 | |

|

SW |

G |

mm |

19 | 24 | 30 | 30 | 36 | 46 | 60 | 65 |

| 1) | Version "...A80..." |